Colletion box.jpg

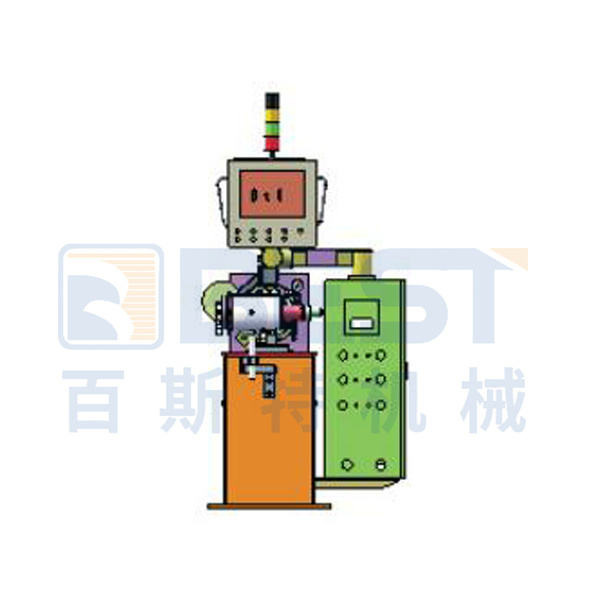

Knittingmachine.jpg

Cuttingmahcine.jpg

Extruder(1698981964463).jpg

Tractionmachine.jpg

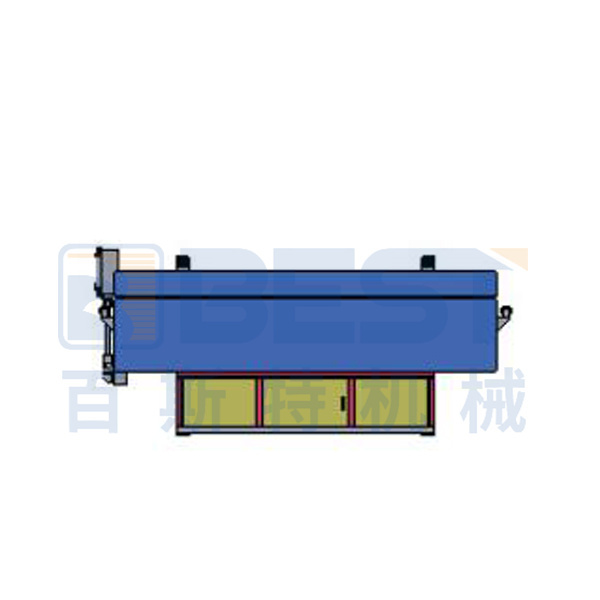

Heatingequipment.jpg

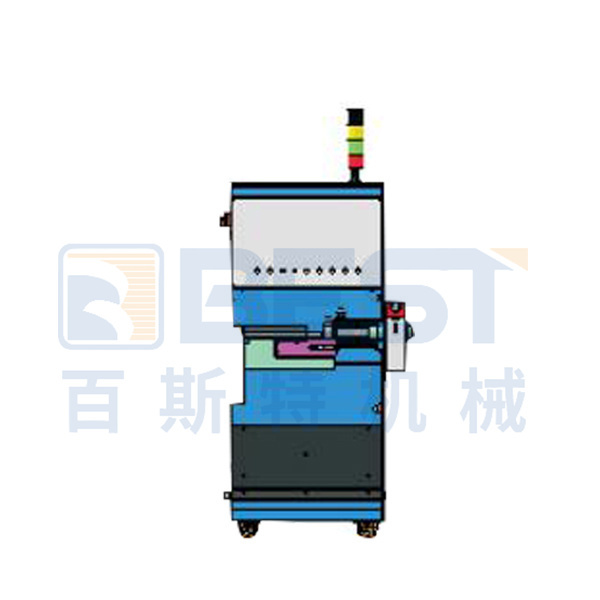

Caliper(1698981955817).jpg

Extruder-1(1698990225481).jpg

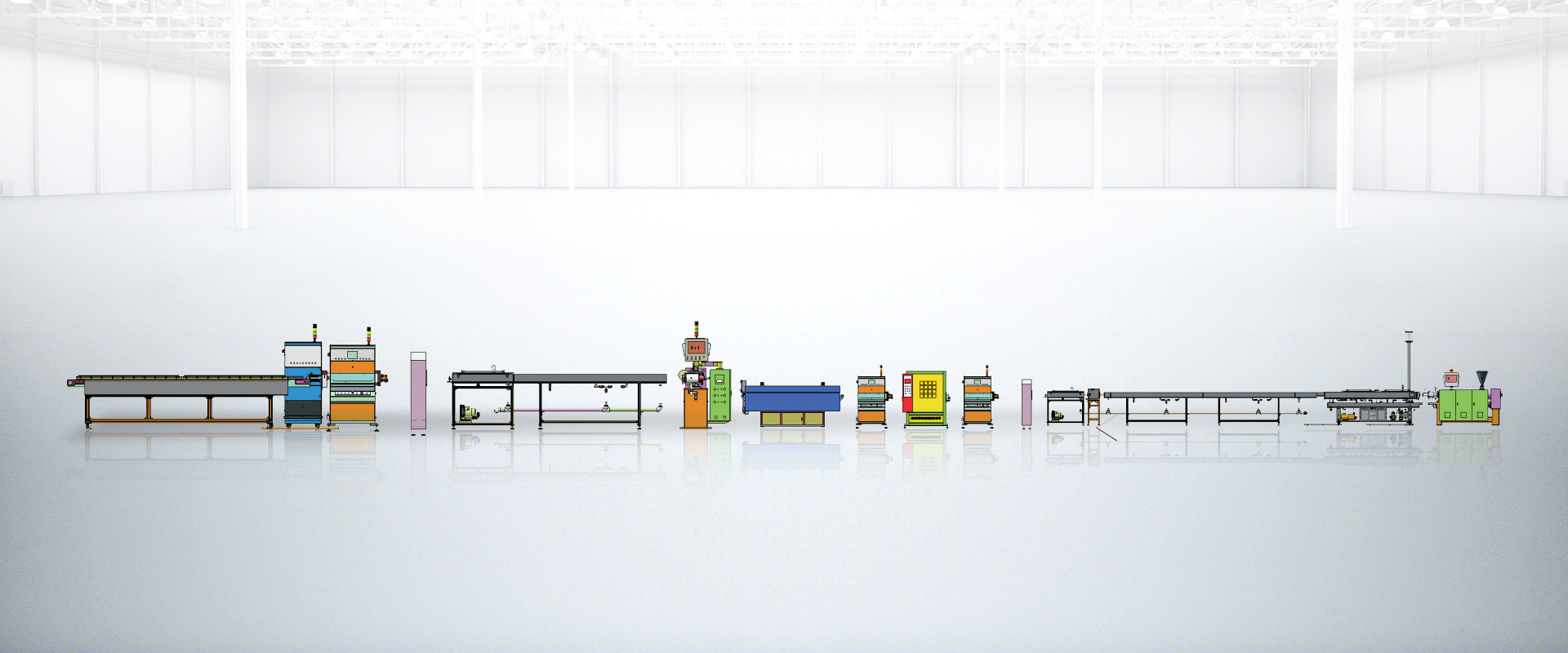

The TPV knitted composite pipe extrusion line

Keywords:

The TPV knitted composite pipe extrusion line

Category:

The TPV knitted composite pipe extrusion line

DESCRIPTION

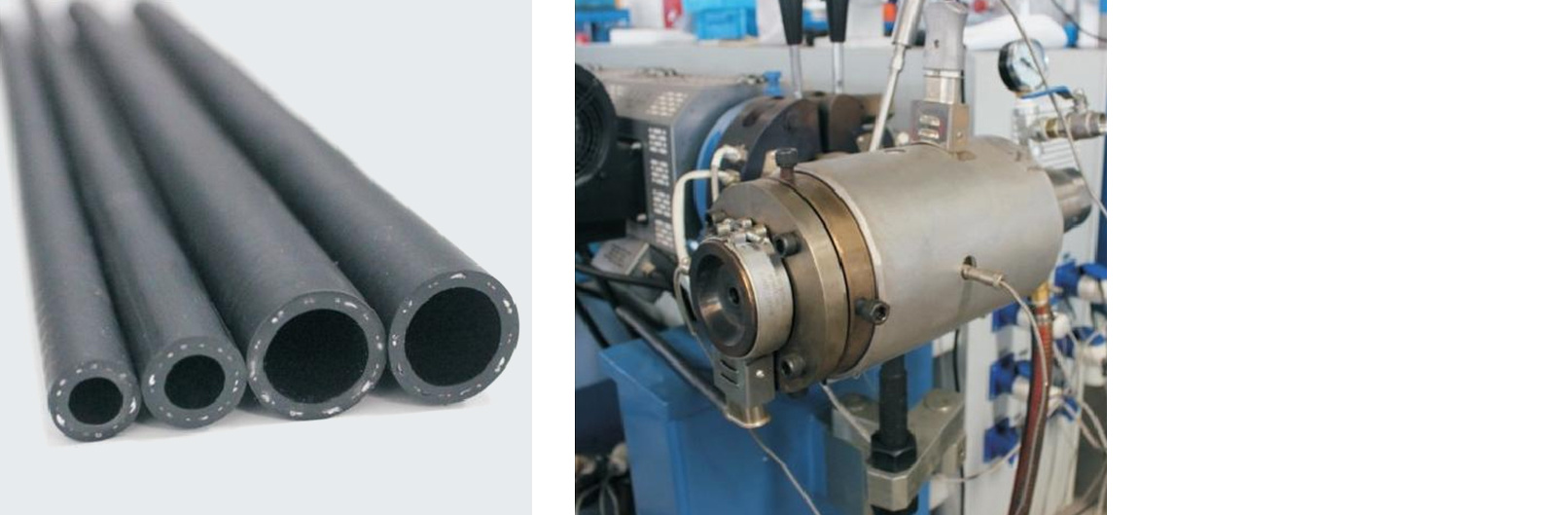

The TPV knitted composite pipe extrusion production line launched by Best adopts a combination method of inner layer TPV + middle knitted layer + outer layer TPV composite coating, which can meet the production plans of three product structures: TPV knitted composite pipe, double layer TPV composite pipe, and single layer TPV pipe. The product is mainly used in the pipeline components of the new energy vehicle battery cooling assembly.

In recent years, thermoplastic elastomer TPV has the characteristics of both rubber and plastic. Compared with other polymer materials such as rubber, the product is lighter in weight, stronger in sealing, has a longer service life, and is more sustainable in manufacturing and recycling. It is also widely used in the fluid pipeline of Alternative fuel vehicle.

MESSAGE

Add: No.17,Xinggang Road,Chengnan High-tech Pioneer Park,Xiangshan County,Ningbo City,Zhejiang Province

Tel: +86-574-6500-2626 Fax: + 86-574-6592-8678

E-mail:shelley@nbbstjx.com E-mail:wuhaizhong@nbbstjx.com / xsbstjx@163.com